Selecting the appropriate flight case hardware is crucial for ensuring the safe transport of your valuable equipment. This guide will help you choose the right flight case and the best hardware to meet your specific needs. From understanding the different types of flight cases to selecting the perfect flight case handle, this case guide will cover everything you need to know to make an informed decision. Whether you’re transporting delicate electronics, musical instruments, or any other sensitive items, this guide will ensure you pick the right flight case for the job.

Understanding Flight Cases

What is a Flight Case?

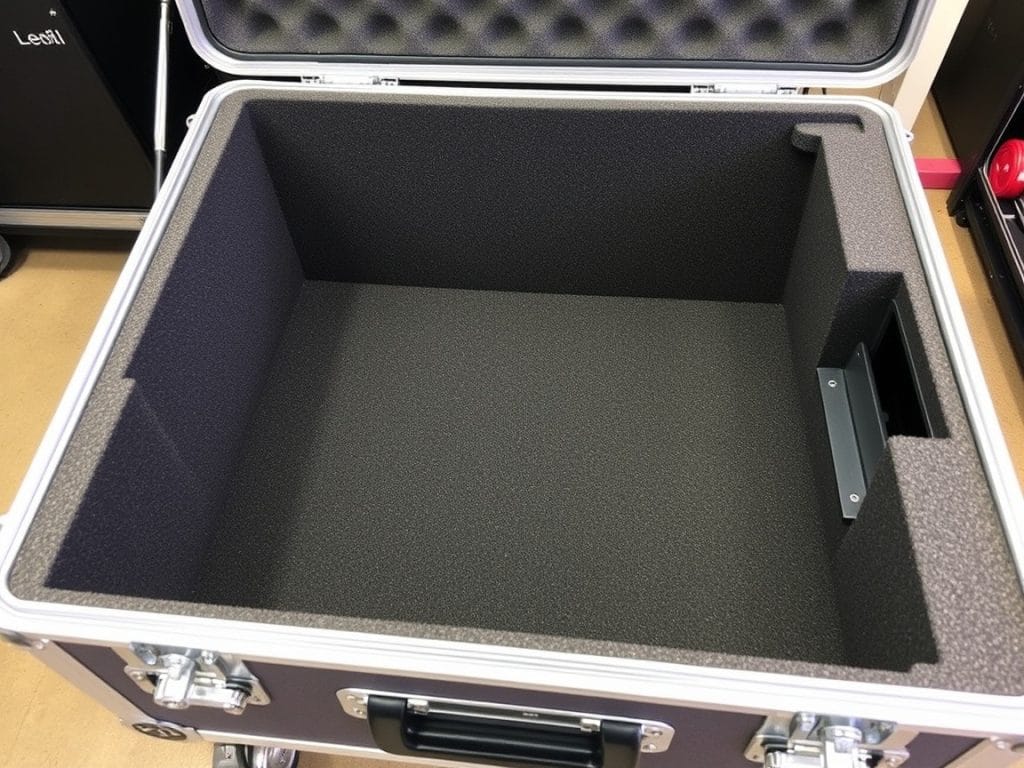

A flight case is a specialized type of equipment case designed to protect valuable equipment during transport, making selecting the right case essential for all users. Typically constructed using durable materials such as plywood and reinforced with metal edges and corners, a high-quality flight case is built to withstand the rigors of frequent use and demanding transit. These cases often incorporate foam inserts that are custom-cut to cradle specific items, providing additional shock absorption and preventing movement during transport. Flight cases are frequently used as road cases by musicians, photographers, and other professionals who need to transport delicate equipment safely and securely.

Importance of Choosing the Right Flight Case

Choosing the right flight case is paramount for ensuring the durability of your valuable equipment during transport. A high-quality flight case not only provides a protective shell but also helps to organize and secure items, preventing damage from impact, vibration, and environmental factors. The right flight case should be selected based on your needs and considering factors such as size, weight, and the type of equipment being transported inside the case. Investing in the right flight case ensures that your valuable equipment arrives at its destination in optimal condition, safeguarding against costly repairs or replacements.

Different Types of Flight Cases

Different types of flight case designs cater to a wide range of needs, making selecting the right case hardware crucial for optimal functionality. Some flight cases are specifically designed for audio equipment, featuring compartments for mixers, amplifiers, and cables. Others are tailored for musical instruments, cameras, or even delicate scientific instruments. Large flight cases often incorporate casters and retractable handles for easy portability, while smaller transit cases may focus on minimizing weight and bulk. Understanding the different types of flight case options available will help you choose the right case to provide the best protection and portability for your specific equipment.

Flight Case Hardware Essentials

Overview of Flight Case Hardware

Selecting the correct flight case hardware is essential to the durability and longevity of your equipment’s protection. Flight case hardware encompasses all the components that contribute to the structural integrity and functionality of the case, including handles, latches, hinges, and corner protectors. These elements are designed to withstand the rigors of transport and frequent use, ensuring your valuable equipment remains safe from damage. Choosing the right hardware is as crucial as selecting the flight case itself, as even the most durable case can be compromised by substandard hardware. The goal is to choose the right flight case hardware that can handle the weight of the case and the equipment inside.

Key Components: Handles, Latches, and More

When selecting flight case hardware, several components are essential. These include:

- Handles, designed for comfortable portability, with ergonomic options reducing strain during transport.

- Latches, which ensure the case remains securely closed, protecting against accidental openings; consider heavy-duty latches with a reliable locking mechanism for added security.

Casters, especially for large flight cases, enhance portability, making it easier to move heavy equipment. The overall goal is to ensure the handle’s design and the right hardware support both the durability and functionality of the equipment case. For smaller transit cases, recessed handles may be ideal to minimize bulk. Different types of flight case hardware cater to varied needs.

Factors to Consider When Selecting Hardware

When choosing flight case hardware, several factors should be considered to ensure optimal performance and durability. Specifically, it’s important to:

- Evaluate the weight of the case and its contents to select handles and latches that can withstand the load.

- Consider the frequency of use; for road cases and equipment cases subject to frequent use, invest in heavy-duty hardware that can withstand wear and tear.

Material quality is also crucial; opt for high-quality flight case hardware made from robust materials like steel or aluminum for longevity. Evaluate ergonomic factors, particularly for handles, to ensure comfortable handling and reduce strain. Choosing the right handles involves considering how they enhance portability and prevent discomfort.

Choosing the Right Handles for Your Flight Case

Types of Handles for Flight Cases

Choosing the right handles for your flight case involves understanding the different types available. Each offers distinct advantages, so consider these options:

- Recessed handles, ideal for transit cases, sit flush with the surface to save space.

- Surface-mounted handles provide a more ergonomic grip, perfect for larger flight cases needing robust lifting support.

Spring-loaded handles offer a comfortable and secure grip, reducing strain during transport. The best hardware depends on usage frequency and the case’s weight, so evaluate your specific needs carefully.

Durability and Material Considerations

Durability is a key factor when selecting handles for your flight case. High-quality flight case hardware, particularly handles, should be constructed from robust materials like steel or aluminum to withstand frequent use and the rigors of transport. The handle’s material should also be resistant to corrosion and environmental factors to ensure longevity. Consider handles with reinforced mounting points to prevent them from pulling away from the case under heavy loads. Investing in durable handles ensures that your valuable equipment remains safe and secure during transport. A durable handle ensures you can transport your road cases without worry. Plywood cases often benefit from robust handles that can withstand the weight of the case.

How to Choose the Right Handle for Your Needs

Choosing the right handles for your flight case involves considering several factors to ensure optimal portability and durability, which is a popular choice among users. First, evaluate the weight of the case and its contents to select handles that can comfortably withstand the load. Consider the ergonomic design of the handles; handles are designed to be comfortable and reduce strain during transport. For large flight cases, retractable handles and casters can greatly enhance portability, making it easier to move heavy equipment. Evaluate the frequency of use and the environment in which the case will be used to select handles that can withstand wear and tear. By carefully assessing your needs and the available options, you can choose the right flight case handle that provides both comfort and reliability, making sure your flight case is equipped with the best hardware.

Best Practices for Flight Case Transport

Portability and Transit Considerations

When transporting your valuable equipment in a flight case, portability is a key consideration, especially when selecting a flight case that meets your needs. For large flight cases, retractable handles and casters are essential for easy maneuverability. The right flight case handle, designed with ergonomics in mind, can significantly reduce strain during transport. Always assess the weight of the case and its contents to ensure the handles are designed to withstand the load. For transit cases, consider the overall size and weight to ensure they are easy to carry and manage. Remember, the goal is to choose the right handles and hardware that allow you to transport your equipment safely and efficiently, preventing unnecessary strain or injury, while ensuring the case’s durability.

Securing Your Equipment: Locking Mechanisms

Ensuring your valuable equipment is secure inside the flight case is crucial, and the locking mechanism of the latches plays a significant role. Opt for heavy-duty latches with a reliable locking mechanism to prevent accidental opening during transport. High-quality flight case hardware includes robust latches that can withstand the rigors of travel and frequent use. Consider adding padlocks or other security measures for added protection, especially for road cases or cases containing high-value items. Always check that the latches are properly engaged before transporting the case to prevent damage to your equipment. Investing in robust latches is vital for the durability of the equipment case.

Handling Cases with Foam Inserts

Foam inserts are essential for protecting your valuable equipment inside a flight case. When handling cases with foam inserts, ensure that the equipment is properly seated and secured within the custom-cut compartments. Avoid placing excessive weight on the foam inserts, as this can compress or damage them, reducing their protective capabilities. Regularly inspect the foam inserts for wear and tear, replacing them as needed to maintain optimal protection for your valuable equipment inside the case. Also, ensure that the foam doesn’t interfere with the locking mechanism or the latches, compromising the case’s security. High-quality foam is important to the hardware. The right flight case hardware will have been designed to account for them.

Conclusion: Building the Perfect Flight Case

Summary of Key Points

In summary, selecting the perfect flight case involves careful consideration of several key factors. The right flight case hardware, including handles, latches, and casters, plays a crucial role in ensuring portability and durability. Choosing the right handles that are designed for comfort and ergonomic use is essential, especially for large flight cases. Material quality and construction are paramount for withstanding frequent use and the rigors of transport. Always assess your needs and the type of equipment being transported to choose the right flight case and hardware for optimal protection.

Final Recommendations for Choosing Hardware

For final recommendations when choosing flight case hardware, prioritize high-quality materials such as steel or aluminum for maximum durability. Opt for heavy-duty latches with a reliable locking mechanism to secure your valuable equipment. Select handles that are ergonomically designed for comfortable handling and can withstand the weight of the case. Consider retractable handles and casters for large flight cases to enhance portability. Always choose the right hardware that meets your specific needs and ensures the safe transport of your equipment. The right handle will make all the difference on road cases.

Future Trends in Flight Case Design

Future trends in flight case design are focusing on enhanced durability, lighter materials, and smarter features. Expect to see more cases constructed from advanced composites that offer superior impact resistance while minimizing weight. Integrated tracking systems and smart locking mechanisms will provide added security and peace of mind. Ergonomic handles and retractable handles will continue to evolve for improved comfort and portability. Customization options will become more prevalent, allowing users to tailor their flight cases to their specific needs, making selecting the right flight case even more essential. Overall, the future of flight case design is geared towards providing the right hardware and the right flight case for your valuable equipment during transport.