Kingway Metal is your reliable partner for high-quality flight case hardware. Our case corner braces are engineered to provide unparalleled protection and durability, ensuring your valuable equipment remains safe during transport. Explore how our flight case hardware solutions can enhance the structural integrity of your cases, offering you peace of mind and professional performance.

Understanding Flight Case Hardware

What is a Flight Case?

A flight case, often referred to as a road case, is a specialized type of case meticulously designed to protect sensitive equipment during transportation. These robust cases are ideal for professionals in various industries, including music, entertainment, and technology, where equipment is frequently moved between locations. The primary purpose of a flight case is to deliver reliable protection against the rigors of travel, such as impacts, vibrations, and environmental factors. They are built to withstand the demands of the road, ensuring that the equipment inside remains in perfect working condition, even when using a ball for added stability.

Importance of Quality Flight Case Hardware

Quality flight case hardware is paramount for ensuring the durability and reliability of flight cases, especially when transporting sensitive equipment. Flight case manufacturers demand robust hardware that can withstand frequent handling and harsh environments. The case corner, case braces, and other components must reinforce the case to prevent damage. High-quality flight case hardware ensures the structural integrity of the case, maintaining its ability to protect the contents from impacts, vibrations, and environmental factors. Investing in durable flight case hardware accessories, including a protective wrap, is crucial for extending the lifespan of the flight case and safeguarding valuable equipment.

Components of a Flight Case

A flight case comprises several essential components, each playing a crucial role in providing maximum protection. Key elements that contribute to the case’s robustness include:

- The panel, forming the main body of the case, often constructed from durable materials like plywood or aluminum.

- Flight case hardware accessories, such as hinges, latches, and handles, ensuring secure closure and easy handling.

These components work together seamlessly to create a robust and reliable road case, capable of withstanding the rigors of transportation.

Types of Braces and Their Applications

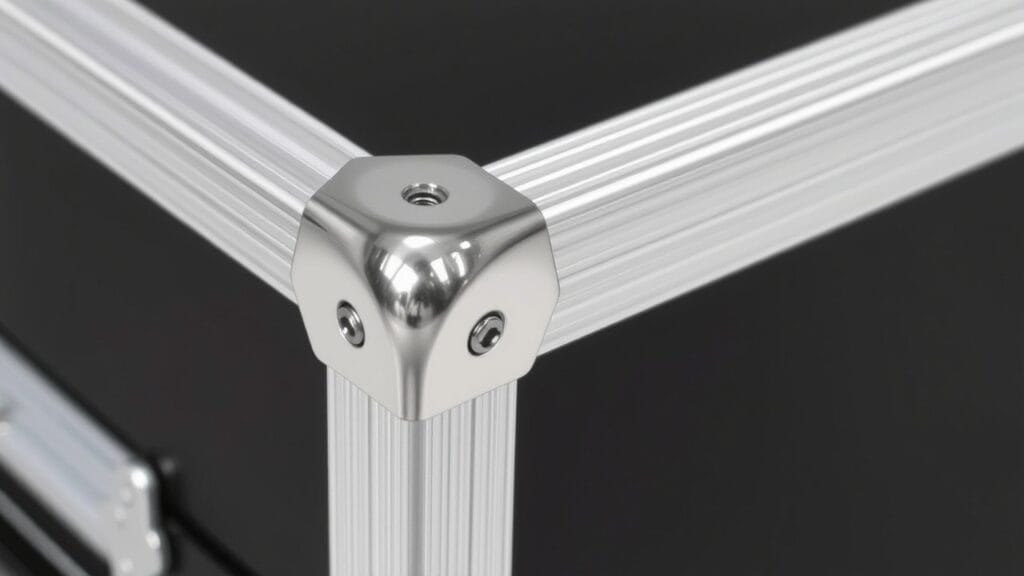

Overview of Corner Braces

Corner braces are essential components in the construction of robust structures, and at Kingway Metal, we design and manufacture high-quality flight case corner braces to deliver reliable support and protection. A corner brace, which can be enhanced with a wrap, is a bracket designed to reinforce the joint between two surfaces, typically at a 90-degree angle. These braces, available in a variety of sizes and styles, can be paired with ball mounts to suit various applications. The primary function of a flight case corner brace is to provide structural support and enhance the durability of the case, ensuring it can withstand impacts and vibrations. Made from materials like steel or aluminum, the corner brace ensures that the case corner remains intact, even under heavy use. The inclusion of mounting holes in the design facilitates easy installation of clamps, making them an ideal choice for flight case manufacturers.

Benefits of Using Metal Braces

Metal braces offer numerous benefits, including compatibility with clamps, making them a preferred choice for reinforcing flight cases and road cases. The strength of metal ensures that the case corner and overall structure remain stable, even when subjected to harsh conditions. Metal braces, particularly those made from steel or aluminum, provide excellent durability, extending the lifespan of the flight case. At Kingway Metal, our flight case hardware accessories are designed to maintain the structural integrity of your equipment cases. The use of high-quality metal braces reinforces the corners and edges, offering enhanced protection against impacts, vibrations, and other forms of stress. Investing in metal braces is a cost-effective way to ensure that your valuable equipment remains safe during transport, offering peace of mind and professional performance.

Performance of Heavy Duty Braces

Heavy duty braces, when combined with clamps, are designed to provide maximum support and stability for flight cases that require extra reinforcement. These braces are constructed from robust materials, such as thick steel, to withstand significant loads and impacts. The design of heavy duty braces often includes additional features, such as gussets or flanges, to further enhance their strength. Our flight case hardware range include flight case corner braces, and they are perfect for cases containing heavy or sensitive equipment. The performance of heavy duty braces is crucial in maintaining the structural integrity of the case, preventing deformation and damage during transportation. Whether you are building a road case for musical instruments or a flight case for electronic equipment, heavy duty braces deliver reliable protection, ensuring your equipment arrives in perfect condition. Many customers compare our quality to Penn Elcom’s and choose cases with Penn Elcom.

Features of Kingway Metal Corner Braces

Construction and Design

Kingway Metal Co., Ltd excels in the stamping and assembling of high-quality flight case hardware, and our case corner braces are a testament to our expertise. We emphasize customization, offering a wide range of standardized options, including clamps, to perfectly fit your specific needs.. Whether you need a case corner brace, flight case hardware, or any other accessory, Kingway Metal is dedicated to providing one-stop solutions for all your case hardware requirements. Our meticulous design ensures that each corner brace delivers reliable performance and is ideally suited for various applications, reinforcing the structural integrity of your flight case.

Durability and Strength

Kingway Metal is a trusted supplier of flight case hardware to premium plastic flight case manufacturers in America and Europe, especially those requiring black E-coating surfaces, made of stainless steel (304, 316L/V4A) with black E-coating surface. We also provide flight case hardware made of carbon steel, ensuring a durable and strong solution for any case corner or brace need. The strength of our metal braces guarantees stability and protection, and we highlight the importance of zinc plating for corrosion resistance, particularly in humid climates. This ensures the durability of our flight case hardware, maintaining its structural integrity even in demanding environments. Our heavy duty braces and flight case corner braces are designed to withstand the rigors of transport.

Black Finish and Aesthetic Appeal

Our flight case hardware, including case corner braces, are available in a sleek black finish, offering both protection and aesthetic appeal. This black finish is not just for looks; it provides an additional layer of protection against wear and tear, while a protective wrap maintains the professional appearance of your flight case. The black finish complements the overall design, ensuring your equipment looks as good as it performs. Our commitment to high-quality means we provide durable finishes that withstand the demands of road cases, flight cases, and other professional applications. Choose Kingway Metal for flight case hardware that delivers reliable performance and a touch of sophistication. The black finish fits our flight cases with Penn Elcom.

Installation and Maintenance of Flight Case Corner Braces

Installation Tips for Corner Braces

Installing flight case corner braces properly is crucial for ensuring maximum support and longevity of your case. The process includes several important steps, such as:

- Selecting the appropriate size and style of corner brace for your specific application, ensuring it fits snugly against the case corner.

- Using mounting holes to align the corner brace accurately with the edges of the case, guaranteeing a secure and even distribution of support.

When securing the brace, use screws or rivets that are suitable for the material of your flight case and brace. For metal cases, steel or aluminum rivets often provide the most durable connection. Ensure that all fasteners are tightened adequately to prevent loosening over time, which could compromise the brace’s ability to reinforce the case.

Maintaining Your Flight Case Hardware

Maintaining your flight case hardware, including clamps and wraps, is essential for ensuring the continued performance and durability of your equipment cases.. Regularly inspect your flight case corner braces for signs of wear and tear, such as dents, scratches, or corrosion. Clean the metal hardware with a mild detergent and a soft cloth to remove dirt and grime, which can accelerate corrosion. Lubricate hinges and latches periodically to keep them functioning smoothly. If you notice any loose fasteners, tighten them promptly to prevent further damage. For cases used in humid environments, consider applying a corrosion inhibitor to the hardware to maintain its integrity. Proper maintenance will extend the life of your flight case and its hardware, ensuring your equipment remains protected.

Common Issues and Solutions

Common issues with flight case corner braces often involve loose fasteners, corrosion, or physical damage from impacts. If you notice loose screws or rivets, tighten or replace them immediately to maintain the structural integrity of the corner. Corrosion can be addressed by cleaning the affected area and applying a corrosion inhibitor, especially for steel hardware. In cases where the corner brace is bent or significantly damaged, replacement is often the best solution to ensure reliable protection. Ensure the replacement brace is of high-quality and fits the specifications of your flight case. Regular inspections and prompt repairs will prevent minor issues from escalating into major problems, maintaining the case’s ability to protect your valuable equipment. The performance of the case corner is a must; therefore, maintaining it is vital.

Choosing the Right Flight Case Accessories

Must-Have Accessories for Your Flight Case

Selecting the right flight case hardware accessories can significantly enhance the functionality and protection of your cases. For example, you can reinforce the case’s structure and usability by focusing on elements like:

- Telescopic runners for normal extraction and soft-close mechanisms to ease handling.

- Steel zinc plated case corners are indispensable for reinforcing vulnerable points and prolonging the lifespan of the case.

Small stainless steel case latches ensure secure closure, preventing accidental openings during transport. Additional accessories might include internal padding, dividers, and custom foam inserts tailored to your equipment. Flight case hardware accessories like handles and wheels, along with a sturdy clamp, facilitate easier mobility. Incorporating these accessories transforms your flight case into a customized, high-performance solution.

Evaluating Accessory Quality

When choosing flight case hardware accessories, evaluating the quality is paramount to ensure reliable performance and long-term durability. Look for accessories made from robust materials like steel or aluminum, as they provide superior strength and resistance to wear. Check for precise construction and smooth finishes, as these indicate attention to detail and quality craftsmanship. Examine the load ratings of handles, wheels, and braces to ensure they can withstand the weight of your equipment. Ensure that latches and hinges operate smoothly and securely. Flight case corners with black E-coating surfaces, made of stainless steel (304, 316L/V4A), demonstrate superior corrosion resistance. Investing in high-quality hardware ensures your flight case maintains its structural integrity, safeguarding your valuable equipment.

Compatibility with Different Flight Case Styles

Ensuring compatibility between accessories, such as clamps and wraps, and different flight case styles is crucial for optimal performance and fit.. Consider the dimensions and construction of your case when selecting corner braces, latches, and handles. For example, heavy-duty cases may require larger, more robust corner braces to provide adequate support, while smaller cases may benefit from more compact hardware. Verify that the mounting holes align correctly and that the accessories fit snugly against the case panel. Flight case hardware accessories like telescopic runners need to be compatible with the internal dimensions of the case and any wraps used to function properly. Compatibility ensures that all components work together seamlessly, maximizing the protection and functionality of your flight case and other road case or cabinet. Our design fits our cases with Penn Elcom and other brands.