Ensuring your flight case is equipped with the right hardware is crucial for protecting valuable equipment during transport. A key component is the recessed handle, designed for durability and ease of use. This guide provides a comprehensive, step-by-step approach to installing recessed flight case handles, ensuring a secure and professional finish.

What Is a Recessed Flight Case Handle?

A recessed handle is a type of case hardware designed to sit flush with the case surface, creating a sleek and unobtrusive profile. This design is particularly useful for flight cases and road cases, where minimizing protrusions is essential for easy stacking and transport. The recessed design prevents the handle from being easily damaged during transit. Often spring loaded, the handle springs back into the recess when not in use. Using reliable hardware like recessed handles in flightcase construction enhances both the case’s functionality and its aesthetic appeal, making it a popular choice for various applications. The correct fitting of a recessed handle involves careful measurements and precise installation techniques to ensure it operates smoothly and remains securely attached to the case.

Benefits of Recessed Handles

Recessed handles offer several advantages for flight cases and road cases. Their flush design minimizes the risk of damage during handling and transit, preventing snagging on other equipment or surfaces. This is especially important for touring professionals who frequently transport heavy-duty equipment. The compact design of the recessed handle also allows for easier stacking and storage of cases, optimizing space in transport vehicles and storage facilities. Furthermore, the flush handle sits flush with the case surface, providing a clean, professional look that enhances the overall appearance of the flight case or speaker cabinets. The choice of material, such as stainless steel, ensures durability and resistance to corrosion, making recessed handles a reliable choice for long-term use.

Common Use Cases

Recessed handles are commonly used in a variety of applications where durable and space-efficient case hardware is required. In the entertainment industry, they are essential for flight cases that transport sensitive equipment such as musical instruments, audio equipment, and lighting systems. The robust design ensures that these items are well-protected during frequent tours and performances. Recessed handles are also popular in diy road case construction, where custom cases are built to specific dimensions and requirements. Additionally, these handles find use in industrial settings for transporting tools, electronic components, and other valuable items, offering a secure and reliable solution. Flight case manufacturers require hardware that can withstand frequent handling and harsh environments, making recessed handles a standard choice.

Tools and Materials Required

Before starting the installation of a recessed flight case handle, gathering the necessary tools and materials is essential for a smooth and efficient process. Having everything at hand will not only save time but also ensure a professional and secure installation. Ensuring you have the right tools and materials will enable you to achieve a perfect fit and a durable, long-lasting result, essential for protecting your valuable equipment during transit.

Essential Tools Checklist

To properly install a recessed flight case handle, you will need several essential tools. Many of these tools help with accurate placement and secure installation and include:

- A measuring tape and pencil for accurate marking and alignment are essential when preparing for heavy-duty recessed handle installation.

- A screwdriver, appropriate for the type of screws you choose, for securing the handle in place.

A drill is necessary for creating mounting holes, and a drill bit set will provide the right size bits for the screws or rivets you’ll be using. If you opt for rivets, a rivet gun will be required. Safety glasses should always be worn to protect your eyes from debris. Depending on the case material, a countersink bit may be useful for creating a flush surface for the handle. These tools will ensure that your recessed handle is installed safely and securely, providing reliable performance for your flight case or diy road case.

Choosing the Right Handle Size

Selecting the right size recessed handle is crucial for both functionality and aesthetics. The handle fit should be proportional to the size and weight of the case to ensure comfortable and secure handling, especially when dealing with a loaded case. Consider the dimensions of the recess in your flight case and choose a handle that fits snugly without being too tight or too loose. Measure the available space accurately before purchasing handles from a hardware store. A large recessed handle might be necessary for larger cases that carry heavier loads, while a smaller handle will be suitable for smaller, lighter cases. Ensure the handle dimensions align with the thickness of the case material for a flush, professional fit, and consider adding washers if the screw holes are too large; this is especially important for large cases.

Preparing the Flight Case for Installation

Measuring and Marking the Cutout

Before installing the recessed handle, precise measurements are crucial for achieving a professional fit. Begin by measuring the recess on the flight case where the handle will be fit. Use a measuring tape to determine the exact dimensions of the cutout required, ensuring it accommodates the heavy-duty recessed handle perfectly. Transfer these measurements onto the case surface using a pencil, creating a clear outline for the opening. Double-check the measurements to avoid errors. Accurate marking ensures the handle sits flush with the case, preventing any gaps or misalignments during installation. This careful preparation is essential for a secure and aesthetically pleasing result, enhancing the functionality and appearance of your diy road case or speaker cabinets. Kingway Metal emphasizes precision in every step, ensuring our flight case hardware meets the highest standards.

Handle Placement Guidelines

Proper placement of the recessed handle is vital for both ergonomics and structural integrity. Position the handle where it allows for a balanced and comfortable grip, considering the weight of the case when it’s a loaded case. Ensure the handle fits comfortably in the hand without straining. Avoid placing the handle too close to the edges or corners of the case to prevent weakening the structure. Check that the placement doesn’t interfere with other case hardware, such as recessed latches, hinges, or extrusions. If you are constructing a diy road case, simulate carrying the case to determine the most natural and convenient handle position. This attention to detail ensures the flight case is not only functional but also comfortable to use, reflecting the quality and thought that goes into Kingway Metal case handles, including heavy-duty recessed options. Our reliable hardware, including heavy-duty recessed handles, is designed for optimal performance and ease of use.

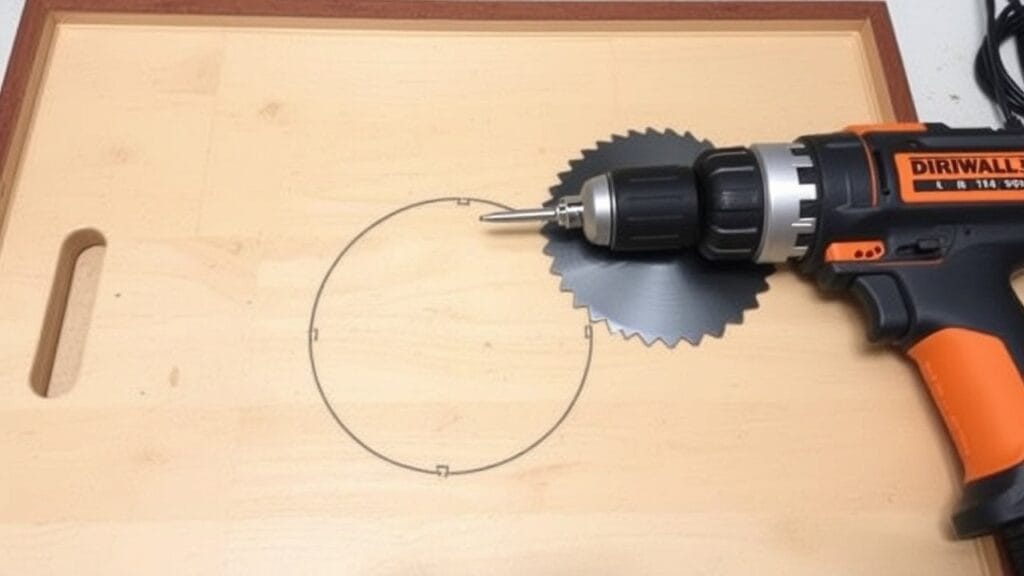

Cutting the Recessed Handle Opening

Once the cutout is accurately marked, the next step is to carefully cut the opening for the recessed handle. Using a drill, create pilot holes at each corner of the marked outline. These holes will serve as starting points for cutting along the lines. Depending on the case material, use a jigsaw or a router with a suitable blade to cut along the marked lines. Maintain a steady hand and follow the lines precisely to ensure a clean and accurate cut. If the case material is aluminum, use appropriate cutting tools designed for metal to prevent damage or deformation, particularly when working with aluminum extrusions. After cutting, smooth the edges of the opening with sandpaper or a file for a professional finish. This ensures the recessed handle fits snugly and securely into the opening, contributing to the overall strength and appearance of the flight case. Kingway Metal provides heavy duty hardware solutions, designed for durable and lasting performance.

Using a Jigsaw or Router Safely

When cutting the recess for the heavy-duty recessed handle, safety is paramount. Always wear safety glasses to protect your eyes from debris when working with large cases. If using a jigsaw, ensure the blade is appropriate for the case material to avoid splintering or damage. For a router, use a guide to maintain a straight and consistent cut. Keep your hands clear of the blade at all times. Work in a well-ventilated area, especially when cutting materials like aluminum or treated wood. Secure the flight case firmly to prevent movement during cutting. Taking these precautions will ensure a safe and precise installation of the flight case handle while minimizing the risk of injury, ensuring that your diy road case construction goes smoothly.

Avoiding Common Cutting Mistakes

Several common mistakes can occur when cutting the opening for a recessed handle. One frequent error is inaccurate measurements, leading to an opening that is either too large or too small. Always double-check measurements before cutting, and use a sharp pencil for precise marking. Another mistake is using the wrong type of blade or bit for the case material, which can result in jagged edges or splintering. Cutting too quickly can also lead to inaccuracies. Take your time and maintain a steady hand. For aluminum cases, using lubricant can help prevent the bit from binding and ensure a cleaner cut. Avoiding these pitfalls will help you achieve a professional, flush fit for your recessed handle, resulting in a superior diy road case.

Installing the Recessed Flight Case Handle

With the opening cut, the next step is installing the recessed flight case handle. Position the handle within the cutout to ensure it fits correctly. Check that it sits flush with the case surface. If using screws, align the handle’s mounting holes with the pilot holes you drilled earlier. For rivets, ensure the mounting holes are appropriately sized for the rivets. Apply a small amount of adhesive caulk around the edge of the handle to provide a watertight seal and prevent vibration. This helps to reinforce the installation. Then, secure the handle with screws or rivets, ensuring they are tightened evenly. The meticulous installation ensures a secure and durable fitting, crucial for a heavy duty flightcase.

Aligning the Handle Correctly

Proper alignment is essential for both the aesthetic appeal and functionality of the recessed handle. Before securing the handle, carefully align it within the cutout, ensuring it is centered and flush with the case. Use a straight edge or ruler to verify the alignment. If the handle is not aligned correctly, it may not operate smoothly and could cause uneven wear on the case. Misalignment can also affect the overall appearance of the flight case or diy road case. Take the time to make fine adjustments before tightening the screws or setting the rivets. This attention to detail will result in a professional-looking and well-functioning installation. Kingway Metal emphasizes precision in our case hardware designs for optimal alignment.

Fastening with Rivets or Bolts

When fastening the heavy-duty recessed handle, you have the option of using rivets or bolts. Rivets provide a clean, permanent fitting, while bolts offer the flexibility of removal if needed. If using rivets, select the right size and material for the case thickness and load requirements. A rivet gun is necessary for setting the rivets securely. For bolts, use washers to distribute the pressure and prevent damage to the case material. Ensure the bolts are the correct length to avoid protruding on the inside of the case. Tighten the bolts evenly to provide a secure and stable installation for the heavy-duty recessed handle. Whether you choose rivets or bolts, proper fastening is crucial for the long-term reliability of the handle. Kingway Metal offers a range of fastening solutions for all your case hardware needs.

Reinforcement and Load Safety

Ensuring adequate reinforcement is paramount, especially when dealing with a loaded case. Reinforcement measures enhance the structural integrity of the flight case, ensuring it can withstand the rigors of transport and handling. By strategically reinforcing critical areas, such as around the handle mounting points, you can significantly improve the case’s ability to bear the weight of the case without compromising its integrity. This attention to detail guarantees a durable and reliable solution, ensuring the safety of your valuable equipment during transit. Prioritizing reinforcement is a key aspect of constructing a high-quality diy road case or modifying speaker cabinets.

Using Backing Plates

To enhance the strength and stability of the recessed handle installation, consider using backing plates. These plates, typically made of metal or durable plastic, are placed on the inside of the case behind the handle to distribute the load over a wider area. Backing plates prevent the case material from being crushed or deformed under heavy loads, particularly when lifting or carrying the case. They also provide additional support for the screws or rivets, preventing them from pulling through the material. Ensure the backing plates are properly sized and aligned with the handle mounting points for optimal effectiveness. The use of backing plates is a simple yet effective way to reinforce the handle and ensure it can withstand the demands of frequent use, making it heavy-duty.

Weight Distribution Best Practices

Proper weight distribution is crucial for the safe and comfortable handling of a flight case. When packing the case, distribute the weight evenly to prevent imbalance and strain on the handle and other case hardware. Place heavier items towards the center of the case and closer to the handle to minimize stress on the case’s structure. Avoid concentrating the weight on one side or corner, as this can lead to uneven wear and potential failure. When lifting the case, use proper lifting techniques, keeping your back straight and bending your knees. By following these weight distribution best practices, you can ensure the flight case is easy to manage and the recessed handle remains securely attached, making it a reliable hardware.

Testing, Finishing, and Maintenance

Load Testing the Handle

After installing the recessed handle, it’s crucial to perform a load test to ensure its integrity and reliability. Gradually increase the weight of the case it is designed to hold, observing any signs of stress or movement in the handle or its mounting points. Check for any gaps between the heavy-duty recessed handle and the case surface, indicating a potential weakness in the fitting. If using screws, ensure they remain tightened and do not loosen under load. For rivets, verify that they hold firmly without any play. A successful load test confirms that the handle can safely support the intended weight of the case, providing peace of mind for transporting valuable equipment. If you are constructing a diy road case this is essential. Kingway Metal emphasizes rigorous testing to ensure our flight case hardware meets the highest standards of performance and safety.

Long-Term Care Tips

To ensure the longevity and performance of your recessed handle, regular maintenance is essential. Periodically check the mounting points for any signs of loosening or corrosion. Tighten screws as needed, and replace rivets if they show signs of wear. Clean the recessed handle and the surrounding area with a mild detergent to remove dirt and debris. Lubricate moving parts, such as the spring-loaded mechanism, with a silicone-based lubricant to maintain smooth operation. For stainless steel handles, a specialized cleaner can help preserve their appearance and prevent rust. These simple maintenance steps will help extend the life of your recessed handle and ensure it remains a reliable hardware for years to come. Properly maintained case hardware ensures the flight case remains ready for tour.

Frequently Asked Questions (FAQ)

Conclusion

By following these proven steps, you can confidently install a recessed flight case handle that is secure, functional, and aesthetically pleasing. Essential elements for a professional result include:

- Accurate measurements, careful cutting, and proper mounting techniques.

- Reinforcing the handle and practicing proper weight distribution to ensure the case can withstand the rigors of transport.

Regular maintenance will extend the life of the handle, providing long-term reliability. Whether you are constructing a diy road case or upgrading existing speaker cabinets, a well-installed recessed handle is a valuable addition. With Kingway Metal case handles, you can trust that your flight case is equipped with high-quality hardware designed for durable performance and peace of mind.