In the realm of transporting sensitive equipment, the choice of hardware is paramount. A seemingly small component, such as a case handle, can significantly impact the safety and ease of transport. Kingway Metal, a leading one-stop hardware manufacturer, presents an in-depth look at the rubber grip flight case handle, exploring its definition, function, and the numerous advantages it offers.

What Is a Rubber Grip Flight Case Handle?

Definition and Primary Function

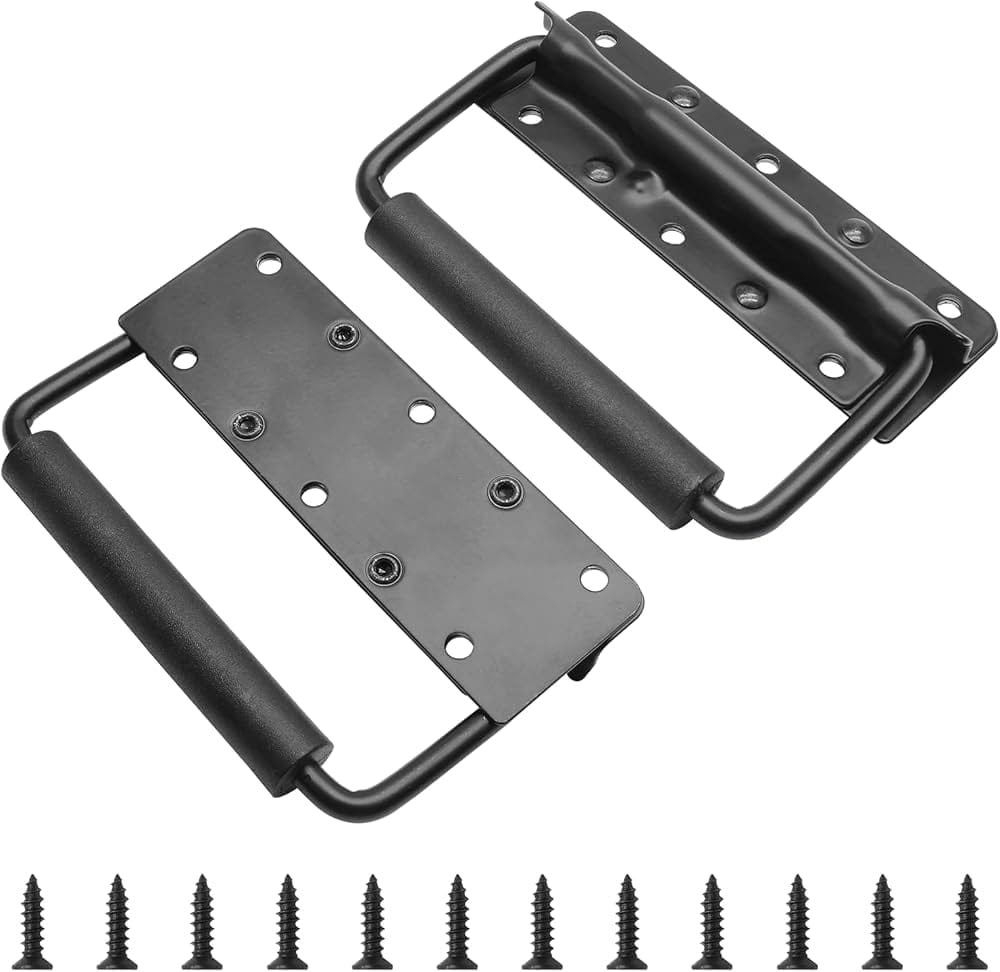

A rubber grip flight case handle is a specialized type of case handle designed for flight cases, road cases, and other heavy-duty applications. The defining feature of this product is the rubber grip that covers the handle’s surface. This rubber grip provides a comfortable and secure hold, enhancing the user’s ability to lift, carry, and maneuver the case effectively. The primary function of a case handle with a rubber grip is to facilitate the safe and convenient transport of equipment, offering a reliable point of contact for the user.

Why Rubber Grips Matter in Professional Use

In professional settings, where equipment handling is frequent and often demanding, the benefits of a rubber grip are amplified. The rubber material offers a superior grip compared to bare metal or plastic, especially in conditions where hands may be sweaty or gloved. This enhanced grip translates to better control over the load, reducing the risk of slips and drops that could damage valuable equipment. Furthermore, the ergonomic design of a handle with a rubber grip minimizes strain on the hands and wrists, making it an essential component for professionals who prioritize both safety and comfort. A black spring-loaded case handle, such as those offered by Kingway Metal, combines durability with user-friendly design.

Key Benefits of a Rubber Grip Flight Case Handle

Enhanced Comfort and Reduced Hand Fatigue

One of the most significant advantages of a flight case handle with a rubber grip is the enhanced comfort it provides. The rubber grip acts as a cushion, minimizing the impact of the case’s weight on the user’s hands. This is particularly crucial when dealing with heavy equipment or during prolonged transport. The ergonomic design distributes pressure evenly across the hand, reducing the likelihood of blisters, calluses, and general hand fatigue. Whether it’s a spring-loaded case handle or a simple cabinet pull, the addition of a rubber grip makes a noticeable difference in user comfort. For those looking to buy cabinet handles or flight case handles, considering a rubber grip is an investment in user well-being.

Improved Grip and Load Control

The primary function of a rubber grip on a case handle is to improve grip and, consequently, load control. The high-friction surface of the rubber material ensures a secure hold, even in challenging conditions. This is especially important when transporting expensive or fragile equipment. Whether you’re dealing with a road case handle or a surface mount handle with rubber, the enhanced grip minimizes the risk of slippage, allowing for more precise and controlled movements. The choice of material, such as aluminum, also contributes to the handle’s strength and durability. Easy installation is another key factor, making these handles a popular choice for DIY projects and professional applications alike.

Common Types of Rubber Grip Flight Case Handles

Recessed Spring-Loaded Rubber Grip Handles

Recessed spring-loaded rubber grip handles are a popular choice for flight cases and road cases where space is at a premium. These handles are designed to fold flat into a recessed area on the case surface when not in use, minimizing the risk of damage during transport or storage. The spring-loaded mechanism ensures that the handle stays securely in either the folded or extended position, making it perfect for a chest handle. The addition of a rubber grip enhances comfort and provides a secure hold, even with heavy equipment inside the case. This type of handle is often seen in speaker cases and other professional audio equipment cases, including those with chest handles.

Surface-Mounted Rubber Grip Handles

Surface mount handles with rubber are another common type, offering easy installation and a robust grip. These handles are attached directly to the surface of the case, making them suitable for a wide range of applications. The rubber grip on a surface mount handle with rubber ensures a comfortable and secure hold, even when carrying heavy loads. Available in various sizes and materials, such as aluminum, these handles can be easily customized to meet specific needs. Whether you need a single handle or a 10 pack, surface-mounted handles are a versatile solution for any case handle requirement.

Materials and Construction Quality

Steel Frames with Rubber Overmolding

The construction quality of a rubber grip flight case handle is crucial for its durability and performance. Many high-quality handles feature a steel frame for strength and rigidity, combined with rubber overmolding for enhanced grip and comfort. The steel frame provides a solid foundation, while the rubber grip absorbs shock and reduces hand fatigue. This combination of materials ensures that the handle can withstand the rigors of frequent use in demanding environments, such as in bags or cabinets. Kingway Metal is committed to using only the finest materials and construction techniques to ensure the reliability of every case handle.

Durability, Shock Absorption, and Finishes

Durability, shock absorption, and finishes are all critical factors to consider when selecting a rubber grip case handle. The rubber material should be resistant to wear, tear, and environmental factors such as UV exposure and temperature variations. Effective shock absorption helps protect the equipment inside the case from damage during transport. The finish of the handle, whether it’s a black spring loaded case handle or a polished aluminum case handle, should be durable and resistant to corrosion. Kingway Metal offers a range of finishes to suit different aesthetic preferences and application requirements, ensuring that your case handle looks as good as it performs. When you buy cabinet handles or flight case handles from Kingway Metal, you are investing in a product designed to last.

Load Rating and Weight Capacity

When considering a case handle with a rubber grip, the load rating and weight capacity are critical specifications. The load rating refers to the maximum weight that the handle can safely support, while the weight capacity indicates the maximum weight of the case and its contents that the handle is designed to carry. Choosing a handle with an appropriate load rating ensures that it will not fail under the weight of the equipment, preventing potential damage and injuries. For instance, a heavy duty aluminum case might necessitate a handle with a higher load rating than a lighter case. It’s essential to carefully assess the weight of the intended load and select a case handle accordingly to guarantee safe and reliable transport of items, such as handles cabinet.

Installation Guide for Rubber Grip Flight Case Handle

Tools and Preparation

Before starting the installation of your new rubber grip flight case handle, proper preparation is key for easy installation. Gather the necessary tools, which typically include a screwdriver (Phillips or flathead, depending on the screw type), a drill with appropriate drill bits (for creating pilot holes if needed), a measuring tape, and a pencil for installing handles cabinet. Ensure the handles cabinet is well-maintained for optimal safety. surface mount area on the case is clean and free from debris. Check the hardware included with the product, such as screws, washers, and any mounting plates. Confirm that the cabinet handles or flight case handles you’ve chosen are the correct size and type for your application, whether they are spring loaded or a folding pull handles are a great option for bags, providing convenience and ease of use.. Taking these preparatory steps will ensure a smooth and efficient installation process of selecting the best chest handle for your item.

Step-by-Step Installation

With your tools and materials prepared, begin the step-by-step process of installing the handles cabinet. installation of your rubber grip flight case handle. First, position the case handle on the case where you want it to be placed, ensuring it aligns with any existing mounting points for the chest handle. Use a pencil to mark the locations for the mounting screws. If necessary, drill pilot holes at these marked spots to prevent splitting the case material. Next, align the handle with the pilot holes and attach it using the provided screws. Ensure the screws are tightened securely, but avoid over-tightening, which could damage the case or the handle. If you’re installing a spring loaded case handle, test the spring loaded mechanism to ensure it functions smoothly. For surface mount handle with rubber, make sure the handle with rubber grip is ideal for a sturdy chest handle. sits flush against the case surface mount. Following these steps will result in a securely installed rubber grip case handle ready for heavy duty use.

How to Choose the Right Rubber Grip Flight Case Handle

Touring, Studio, and Industrial Applications

Selecting the right rubber grip flight case handle depends largely on the specific application. For touring applications, where cases are frequently moved and subjected to rough handling, a heavy duty handle with robust construction and a secure grip is essential. In studio environments, where aesthetics and ease of use are important, a sleek surface mount handle with a comfortable rubber grip might be preferred. Industrial applications often require handles that can withstand harsh conditions and heavy loads, making aluminum or steel handles with durable rubber overmolding ideal. Kingway Metal supplies flight case hardware to premium plastic flight cases manufacturers in America and Europe, often requiring high-quality handles cabinet for industrial items. hardware with black E-coating surfaces made of stainless steel (304, 316L/V4A) are often used in chest handles. Kingway Metal also provides high-quality chest handles. flight case hardware made of carbon steel, catering to diverse case handle requirements.

Maintenance and Care Tips

To prolong the life of your rubber grip flight case handle, regular maintenance and care are essential. Clean the rubber grip periodically with a mild soap and water solution to remove dirt and grime, ensuring a secure grip. Avoid using harsh chemicals or abrasive cleaners that could damage the rubber material. Inspect the handle regularly for signs of wear and tear, such as cracks or loose screws. Tighten any loose handles cabinet to ensure they remain securely attached to the furniture or bag. hardware and replace worn handles promptly to prevent accidents. For spring loaded cases, lubricate the spring loaded mechanism occasionally to ensure smooth operation. Proper maintenance will keep your cabinet handles or flight case handles in optimal condition, ensuring safe and reliable performance for years to come. Whether you buy pull handles, spring handle or surface mount handle with rubber, proper care is the best method to increase handle longevity.

Frequently Asked Questions About Rubber Grip Flight Case Handles

Conclusion

In conclusion, the rubber grip flight case handle offers a multitude of benefits for safer and more comfortable transport of valuable equipment. From enhanced comfort and improved grip to increased durability and reduced hand fatigue, these handles are an essential component for any case requiring reliable and ergonomic hardware. Whether you’re a touring musician, a studio professional, or an industrial worker, investing in high-quality chest handles is crucial. rubber grip flight case handles is a smart choice. Kingway Metal, as a leading one-stop shop for handles cabinet, offers a variety of options. hardware manufacturer provides a wide range of handles cabinet options for various items. case handles to meet your specific needs. Explore our selection of black spring loaded case handles, surface mount handle with rubber, and other heavy duty options to find the perfect handle for your case. We can also help you with DIY projects, offering easy installation and long-lasting quality for your equipment.