Welcome to your comprehensive case guide on selecting the perfect handle for your flight case! Whether you’re transporting musical instruments, sensitive equipment, or other valuable equipment, choosing the right flight case handles is crucial for ensuring safe and efficient transport. This guide will walk you through understanding flight case handles, their types, and why choosing the right flight case hardware is essential for your flight case needs.

Understanding Flight Case Handle

What is a Flight Case Handle?

A flight case handle is a component of case hardware, specifically designed to provide a secure and comfortable grip for carrying a flight case. These handles are built to withstand the rigors of travel, ensuring that you can easily transport your equipment with the help of pull out handles. The handles are designed to support the weight of the case and its contents, making them an indispensable part of any flight case. Whether it’s a small flight case or a large flight case, the right handle makes all the difference. The durability of a flight case handle directly impacts the overall reliability of the case during transit, especially when considering the stress from different types of equipment.

Types of Flight Case Handle

There are several types of flight case handles available, each designed to meet different needs. When you build a flight case, consider what type of handle is best for your needs. The best hardware choice ensures ease of use and longevity. The choice depends on several factors, summarized below:

| Factor | Considerations |

|---|---|

| Case Size & Weight | Heavy-duty handles are designed for large flight cases and can withstand significant weight; strap handles are often used for lighter cases. |

| Handle Type | Recessed handles are set into the case to minimize protrusion and prevent damage; some handles come with additional features like rubber grips for enhanced comfort. |

Importance of Choosing the Right Flight Case Handle

Choosing the right flight case handle is paramount for the safety and convenience of transporting your equipment. The right handle ensures that you can comfortably and securely carry your case, preventing accidental drops or injuries. For heavy or bulky items, a heavy-duty handle is essential to support the weight. Inadequate handles can lead to strain and discomfort, especially over long distances. The correct size and type of handle also contribute to the overall durability of the case. Choosing the best handle ensures that your valuable equipment is protected during transit. It’s an investment in the longevity and functionality of your flight case, complementing other features like foam inserts, latches, and castors.

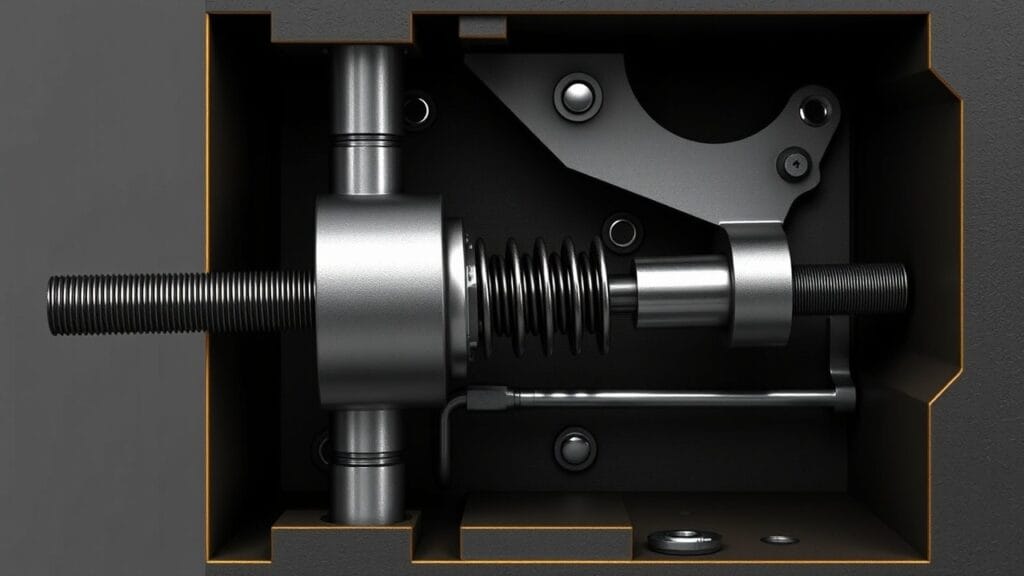

Components of a Flight Case Handle

Flight Case Hardware Size Overview

When selecting flight case hardware, the size of the handle is a critical consideration, influencing both comfort and functionality. A handle that’s too small may not provide adequate grip, especially for large flight cases. Conversely, an excessively large handle can be cumbersome and impractical for small flight cases. The ideal size should allow for a secure, full-hand grip, even when wearing gloves. Consider the typical load your flight case will carry; heavier loads demand larger, more robust handles. Choosing the right flight case handles is essential for easy transit cases. Evaluating flight case sizes and their corresponding handle dimensions will ensure optimal handling and reduce the risk of strain or injury.

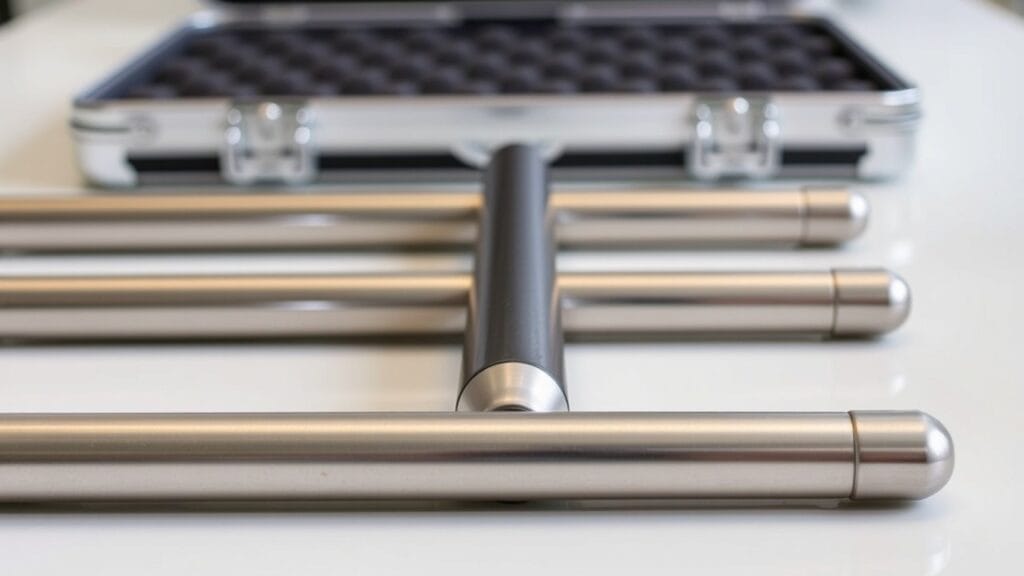

Different Types of Handles for Your Flight Case Handle

Various types of handles cater to different flight case needs. Recessed handles, also known as recessed handles, offer a flush profile, protecting the handle from impacts during transit. Strap handles provide flexibility and are suitable for lighter loads. For heavy-duty applications, opt for handles with reinforced construction and ergonomic grips. Consider materials like carbon steel or stainless steel, particularly those with black E-coating surfaces, offered by suppliers like Kingway Metal, for enhanced durability and corrosion resistance. The choice of handle also depends on the case design; some cases may require specialized mounting hardware. Different handle sizes, shapes and mechanisms provide various benefits for your road case or equipment cases.

Best Hardware for Your Flight Case Handle

Selecting the best hardware for your flight case handles ensures longevity and reliable performance, especially when considering different types of equipment.. High-quality metal, such as stainless steel, offers superior strength and resistance to corrosion, essential for withstanding the rigors of travel. Reinforcements at stress points, like the handle’s mounting points, can significantly enhance durability. Consider handles with rubber grips for improved comfort and reduced slippage. When you build a flight case, the quality of the hardware directly impacts the handle’s ability to support the weight and withstand the stresses of handling. Investing in robust hardware ensures that your handles are built to withstand heavy use and protect your valuable equipment. The best hardware choice ensures ease of use and longevity. This decision impacts the handle’s ability to support the weight and withstand the stresses of handling.

Best Hardware for Your Flight Case Handle

For optimal performance and longevity of your flight case, selecting the best hardware for handles is vital. Kingway Metal emphasizes customization and offers a wide range of standardized options, providing specialized flight case hardware, including stainless steel options with black E-coating, offering excellent durability and corrosion resistance suitable for demanding applications. High-quality materials and manufacturing processes (ISO 9001:2015 certified), and solutions for improved corrosion resistance (zinc plating) should be taken into consideration when selecting components like latches and handles for your flight case.. Consider the specific demands of your application when choosing hardware, such as the need for enhanced corrosion resistance in marine environments or increased load capacity for heavy equipment. With a focus on quality and customization, Kingway Metal is a reliable source for flight case hardware that meets the highest standards of performance and reliability. Consider the best hardware choice ensuring ease of use and longevity.

Choosing the Right Flight Case Handle Size

Factors to Consider When Choosing a Handle

Selecting the right flight case handle size is crucial for both comfort and functionality. Several factors should influence your choice, starting with the overall case size.

| Case Size | Handle Recommendation |

|---|---|

| Small Flight Cases | Smaller handle may suffice |

| Large Flight Cases | More substantial, heavy-duty handle |

Consider the typical load the case will carry; heavier loads necessitate larger handles. The intended use also matters; a guitar case for occasional transport may not need the same robust handle as equipment cases that endure frequent travel. Don’t forget about the user’s hand size and grip strength, ensuring the handles, especially pull out handles, are designed to withstand the conditions of transit cases. Choosing the right flight case handles involves balancing these considerations for optimal performance.

Another critical aspect is the environmental conditions the flight case will face. If the case will be used in humid or corrosive environments, choosing handles with enhanced corrosion resistance is essential.

Zinc plating is a popular and effective method for protecting steel handles from rust and corrosion. Consider handles made from stainless steel or aluminum for superior corrosion resistance. The handles are built to withstand harsh conditions. Durability is an important factor when choosing components like latches and handles for your flight case, especially when considering black hardware options. Regular maintenance can extend the life of your flight case hardware. By carefully assessing these factors, you can ensure the durability and reliability of your flight case handles, protecting your valuable equipment.

Best Flight Case Handles on the Market

When you build a flight case, selecting the best flight case handles can significantly improve its overall functionality and longevity. Kingway Metal offers a variety of high-quality handles designed to withstand the rigors of travel.

Their range includes heavy-duty handles made from carbon steel and stainless steel, available with different finishes such as zinc plating and black E-coating for enhanced durability and corrosion resistance. For recessed handles, look for models with a smooth, ergonomic design that sits flush with the case surface, preventing damage during transit. Whether you need a handle for a small flight case or a large flight case, Kingway Metal provides customizable solutions to meet your specific needs, ensuring your equipment cases are always ready for transit.

Choosing the Right Handle for Different Equipment Cases

Selecting the appropriate handle depends largely on the type of equipment you are transporting. For sensitive equipment like musical instruments, a guitar case requires handles that provide a secure and comfortable grip, minimizing the risk of accidental drops. In such cases, recessed handles are suitable. For heavier equipment, heavy-duty handles with reinforced construction are essential. Also, for larger equipment cases, consider handles positioned to distribute weight evenly, making them easier to carry. Flight case hardware should complement the equipment’s specific needs, ensuring both safety and ease of transport, particularly when dealing with various components like latches. Choosing the right flight case handles is paramount for the safety and convenience of transporting your equipment. These handles are designed to withstand the rigors of travel.

Flight Case Sizes and Their Impact

Understanding Flight Case Handle Sizes

Understanding flight case handle sizes is crucial for ensuring optimal comfort and functionality when transporting equipment. Handles come in various sizes to accommodate different case sizes and weight capacities. Smaller handles are typically suitable for small flight cases, providing a compact and unobtrusive grip. Larger, heavy-duty handles are designed for large flight cases and can withstand the weight of heavier loads. The right handle size ensures a secure and comfortable grip, reducing the risk of strain or injury during transport. Consider the overall dimensions of your flight case when selecting handles to ensure they are appropriately sized for the case and its contents.

How Size Affects Handle Selection

The size of the handle directly affects its suitability for different applications. A handle that is too small may not provide adequate leverage or grip, making it difficult to carry a heavy case. Conversely, an excessively large handle can be cumbersome and uncomfortable to hold. When choosing the right flight case handles, consider the typical weight and dimensions of your equipment cases. Heavy-duty handles with larger grips are ideal for large flight cases containing different types of equipment, while smaller, more streamlined handles may be sufficient for lighter loads. The selection of flight case hardware must align with the practical demands of transit cases.

Choosing the Right Size for Your Equipment

Choosing the right size for your equipment is vital for the long-term safety and usability of your flight case. When selecting the handles for your flight, consider the overall dimensions and weight of your valuable equipment. Smaller handles might be adequate for a guitar case, but will not perform well when trying to lift large flight cases. Selecting the right flight case handles ensures optimal support and stability, particularly when paired with black hardware for a sleek finish. Larger handles are designed to withstand heavier loads, providing a more secure grip and reducing the risk of accidental drops or injuries. By carefully considering these factors, you can choose the best flight case handle size for your needs.

Tips for Selecting the Right Flight Case Handle

Evaluating Your Equipment Needs

Start by thoroughly evaluating your equipment needs when choosing the right flight case handles. Assess the size, weight, and fragility of your equipment cases. For sensitive equipment like musical instruments or electronics, prioritize handles that offer a comfortable and secure grip to prevent accidental drops, particularly when using a telescopic handle. Consider the conditions under which your equipment will be transported; if your flight case will be exposed to harsh environments, opt for handles made from corrosion-resistant materials such as stainless steel with black E-coating. These options are offered by leading case hardware manufacturers. Choosing the right flight case handles that match your equipment’s requirements ensures its safe and secure transit.

Choosing the Right Case for Transit

Choosing the right case for transit depends on several factors, beginning with the size and weight of the contents. Selecting a case made of high-quality materials and designed to withstand the rigors of travel ensures the protection of your equipment. For heavy items, cases with reinforced corners, edges, and heavy-duty handles are essential, particularly when using hardware flight case road case solutions. Pay attention to the latches and hinges; sturdy, reliable hardware ensures that the case remains securely closed during transit. Kingway Metal offers a range of flight case hardware designed to meet these demands, including customizable options to suit specific requirements. It is also important to consider if you need to add castors to provide mobility to your transit cases. Build a flight case tailored to its contents to ensure your items arrive safely and securely.

Working with a Flight Case Manufacturer

Collaborating with a reputable flight case manufacturer like Kingway Metal can significantly streamline the process of selecting the right flight case handle and case hardware. Kingway Metal specializes in providing one-stop solutions for case hardware, offering a wide range of standardized and customizable options. Their expertise ensures that you receive high-quality handles and hardware that meet your specific requirements. They can offer specialized solutions for improved corrosion resistance, such as zinc plating, and stainless steel options with black E-coating for enhanced durability. When you build a flight case, working with a manufacturer that is ISO 9001:2015 certified ensures quality and reliability in every component of your flight case.