When it comes to safeguarding valuable equipment during transport, the often-overlooked component of rubber feet plays a critical role. Kingway Metal understands the importance of these small but mighty protectors, especially for flight cases. We offer a comprehensive range of heavy-duty solutions designed to ensure your equipment arrives safely every time. Our commitment to quality and customization makes us the trusted one-stop hardware manufacturer for discerning professionals who demand the best in protection, stability, and longevity for their valuable equipment.

Understanding Rubber Feet

What Are Rubber Feet?

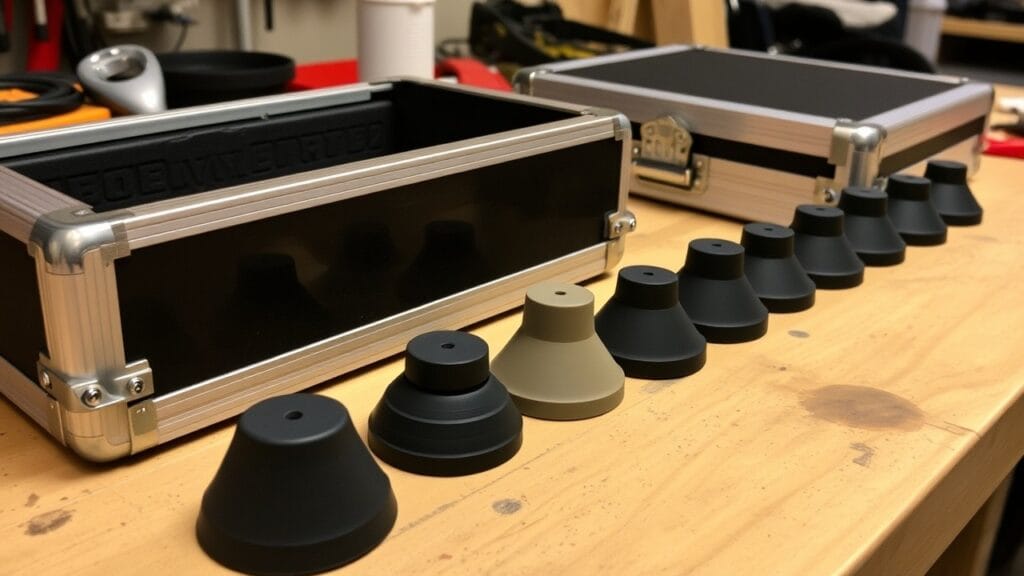

Rubber feet are protective components designed to provide a stable and non-slip base for various items, especially equipment housed in cases. In the context of flight cases and road cases, rubber feet act as a crucial interface between the case and the surface it rests upon. They function as bumpers, absorbing impacts and preventing direct contact that could damage the case or the surface beneath. A rubber foot with a steel insert offers an enhanced product, combining the shock-absorbing properties of rubber with the durability of steel for superior performance.

Materials Used in Rubber Feet

The quality and durability of rubber feet are heavily dependent on the materials used in their construction. While rubber is the primary component, various types of rubber compounds and additional materials like metal or plastic are often incorporated to enhance performance. Heavy-duty rubber feet often feature a high durometer rubber compound for increased wear resistance and load-bearing capacity. Some designs include a steel insert, providing extra strength and preventing the rubber from deforming under heavy loads. The choice of material directly impacts the foot’s ability to absorb vibration, protect against impacts, and maintain its shape over time, especially in demanding road and tour applications.

Benefits of Using Rubber Feet

Employing rubber feet on flight cases offers a multitude of benefits that extend beyond simple aesthetics. The primary advantage is the protection they provide. Rubber feet absorb impacts and vibrations during shipping and handling, safeguarding the equipment inside the case from damage. Furthermore, they prevent the case from directly contacting the surface, reducing wear and tear on both the case and the underlying surface. The added stability offered by case feet prevents the case from sliding or tipping, especially important for heavy equipment. Investing in high-quality, heavy-duty rubber feet ensures longevity for your equipment and cases, reducing the need for costly repairs or replacements. Examples include Penn Elcom and OSP ATA-Rubber-Foot 1.5 which are known for their quality construction and reliable performance.

Importance of Rubber Feet in Flight Cases

Protection of Equipment

One of the most vital functions of rubber feet in flight cases is the protection they offer to the enclosed equipment. During shipping and handling, flight cases are subjected to considerable impacts, vibrations, and general wear and tear. Heavy-duty rubber feet act as a cushion, absorbing a significant portion of these shocks and vibrations to reduce vibration during transport. This helps reduce the risk of damage to sensitive electronic equipment, musical instruments, or other valuable items housed within the case. A strategically placed rubber foot with a steel insert can significantly enhance the protection, providing an additional layer of security against impacts and preventing direct contact between the case and the floor or other surfaces. Investing in high quality rubber feet is a proactive measure to safeguard your equipment and avoid costly repairs or replacements.

Stability During Transport

Beyond protection, rubber feet are crucial for ensuring stability during transport. Whether the flight cases are being loaded onto a truck, carried across a venue, or stacked in storage, the case feet provide a stable base that prevents sliding or tipping. This is particularly important for heavy equipment, where an unstable case could lead to accidents or damage. The increased stability offered by heavy-duty rubber feet minimizes the risk of the case shifting during transit, reducing the potential for internal damage to the equipment. Factors like rubber diameter and height contribute to the overall stability of the case, and selecting the appropriate size and material is essential for optimal performance. Metal feet with a rubber coating also enhance stability and durability.

Longevity of Flight Cases

Investing in quality rubber feet not only protects the equipment inside but also contributes to the longevity of the flight cases themselves. By acting as a bumper, rubber feet prevent the case from directly contacting the ground or other surfaces, minimizing wear and tear on the case’s exterior. This is especially important for cases that are frequently used in road and tour applications, where they are exposed to harsh conditions. Heavy-duty rubber feet, especially those with a steel insert, provide extra strength and resist deformation over time, ensuring that the case maintains its structural integrity. Choosing durable rubber feet that are designed to withstand the rigors of shipping and handling is a cost-effective way to extend the lifespan of your flight cases and protect your investment. We can custom build metal feet or plastic feet with rubber to your specific needs.

Types of Heavy Duty Rubber Feet

Rubber Foot with Steel Reinforcement

A rubber foot with a steel insert is a type of heavy-duty case feet designed to provide enhanced durability and support in demanding applications. The steel insert, typically molded within the rubber, adds extra strength and rigidity to the foot, preventing it from deforming or collapsing under heavy loads. This design is particularly beneficial for flight cases that carry heavy equipment or are subjected to frequent shipping and handling. The combination of rubber and steel provides excellent vibration absorption, protecting the internal equipment from damage caused by impacts and road vibration. These heavy-duty feet are ideal for applications where both protection and stability are paramount. Penn Elcom offers a product line of steel reinforcement feet for durability.

Large Diameter Rubber Feet

Large diameter rubber feet offer a wider surface area for increased stability and load distribution. The larger rubber diameter provides a more secure and stable base for flight cases, especially those containing heavy or top-heavy equipment. This design helps to prevent tipping or sliding, reducing the risk of damage during transport or storage. Large diameter feet also tend to absorb more vibration and impacts compared to smaller feet, further protecting the internal equipment. They are often used in applications where maximum stability and protection are required. Custom designs are available to match the case aesthetic and mounting requirements.

Bumper Rubber Feet Options

Bumper rubber feet serve as protective elements, absorbing impacts and preventing direct contact between the flight case and the surface it rests upon. These heavy-duty feet are designed to protrude slightly from the bottom of the case, acting as a buffer against bumps and scrapes. Bumper feet are particularly useful in road cases and tour applications, where the cases are frequently moved and handled in rough environments. They also help to reduce wear and tear on the case itself, extending its lifespan. Various designs and materials are available, including options with metal or plastic inserts for added durability. The mounting can be done with a screw or bolt, depending on the design.

Choosing the Right Rubber Feet for Your Flight Case

Factors to Consider

Selecting the appropriate rubber feet for your flight cases requires careful consideration of several factors to ensure optimal protection and stability. The weight of the equipment being housed is a primary concern; heavier equipment necessitates heavy-duty rubber feet with a higher load-bearing capacity. The intended application, whether for shipping, road, or tour purposes, also plays a role. Road cases subjected to frequent handling and rough conditions require more durable feet. Consider the mounting method and ensure the rubber foot with a steel insert is compatible with your case design. You should also check the rubber diameter, height, and the material’s ability to absorb vibration and reduce wear.

Installation Tips for Rubber Feet

Proper installation is crucial for maximizing the benefits of rubber feet. Before you begin, consider these important steps:

- Ensure the case surface is clean and dry to promote a secure attachment.

- For screw-on feet, use appropriately sized screws that won’t strip the mounting holes.

- For bolt-on feet, ensure the bolts are tightened securely, but avoid overtightening, which could damage the case or the rubber.

- When using adhesive-backed feet, apply firm pressure for several seconds to ensure a strong bond.

If the case lacks pre-drilled holes, use a template to ensure accurate and consistent placement. Consider consulting with a professional if you’re unsure about the installation process. Our custom build products are tailored to the cases requirements.

Maintaining Rubber Feet for Longevity

To ensure the longevity of your rubber feet and maintain their protective qualities, regular maintenance is essential. This maintenance includes several key steps:

- Periodically inspect the feet for signs of wear, such as cracks, tears, or deformation.

- Clean the rubber surface with a mild soap and water solution to remove dirt and grime.

Avoid using harsh chemicals or solvents, as they can degrade the rubber. If the rubber feet are exposed to extreme temperatures or sunlight, consider applying a rubber protectant to prevent drying and cracking. Replace worn or damaged feet promptly to maintain the stability and protection of your case. We ensure high quality of the product; however, if your rubber feet require replacing, we are happy to provide replacements that fit your flight cases.

Case Studies: Effective Use of Rubber Feet

Real-Life Applications

In the music industry, flight cases equipped with large diameter rubber feet are essential for protecting delicate instruments during transport between venues. Audio engineers rely on rack cases with steel insert feet to provide stability for sensitive mixing equipment in temporary setups. Production companies use heavy-duty rubber feet on road cases to ensure the safe shipping of lighting and staging equipment. From protecting camera equipment on remote shoots to securing medical devices during transport, the applications of well-chosen case feet are diverse and critical.

Customer Testimonials

Many satisfied customers have shared their experiences regarding the importance of quality rubber feet in their flight cases. One customer raved about how metal feet with a rubber coating saved his vintage guitar from damage during a cross-country tour. Another customer praised the durability of the rubber foot with a steel insert, noting that they withstood the rigors of frequent airline travel. A production manager highlighted the increased stability provided by larger rubber diameter feet, which prevented equipment from tipping over during outdoor events. These testimonials underscore the real-world benefits of investing in high-quality rubber feet.

Comparative Analysis of Rubber Feet

When choosing rubber feet, it’s important to consider the various options available and their relative strengths and weaknesses. Bumper feet offer excellent impact protection, while large diameter feet prioritize stability. Rubber feet with a steel insert provide a balance of durability and vibration absorption. Penn Elcom and OSP ATA-Rubber-Foot 1.5 are two popular brands known for their quality. A comparative analysis of these features, along with factors like mounting options, material quality, and price, will help you select the rubber feet that best meet the specific needs of your flight cases. Our custom design offers the right support that meet your requirements.