To identify reliable suppliers of stamping parts (e.g., flight case hardware, construction products) in China, here’s a structured approach based on your criteria and insights from industry practices:

1. Verify ISO Certification and Auditor Credibility

Prioritize suppliers with ISO 9001 (quality management) or ISO/TS 16949 (automotive-specific) certifications. Focus on accredited certifiers like TÜV Rheinland (e.g., webpage 3’s supplier passed ISO 9001/TS 16949 via rigorous audits) or BSI (British Standards Institution). Avoid certifications from lesser-known agencies, as some domestic firms may compromise audit rigor (webpage 2 highlights issues with “buying certificates”).

2. Demand Clear Quality Standards and Documentation

- Ensure suppliers provide detailed specifications (e.g., material grades, dimensional tolerances) and comply with international standards like DIN (Germany), BSI (UK), or JIS (Japan) . For instance, automotive parts often require adherence to VDA 6.3 or Formel-Q7.

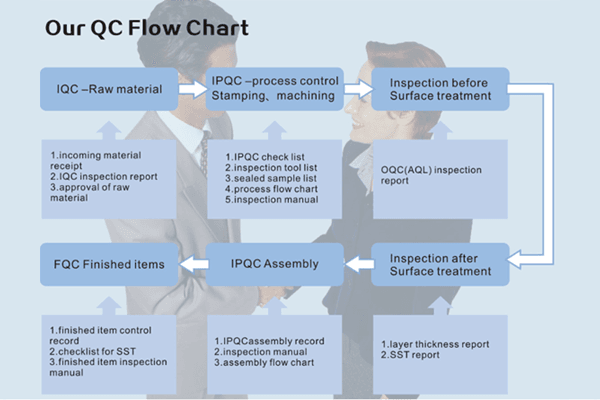

- Require quality documentation, such as Process Flow Charts, PFMEA, and Control Plans, to validate systematic quality management.

3. Evaluate In-House Quality Control Processes

- Inspect facilities for advanced testing equipment (e.g., tensile testers, X-ray flaw detectors) and process controls like SPC (Statistical Process Control).

- Look for multi-stage QC: Raw material checks → In-process inspections → Final product testing. Suppliers with AI-driven defect detection tools (trending in 2025) are advantageous.

4. Assess Supplier Training and Continuous Improvement

- Confirm regular quality training programs for staff. For example, suppliers trained in methodologies like PDCA, 8D, or G8D demonstrate commitment to problem-solving and skill development.

- Check for certified internal auditors (e.g., IATF 16949 auditors) and participation in workshops like QPN (New Parts Quality Development Plan) for automotive projects.

5. Utilize Third-Party Inspection Services

- Engage globally recognized inspectors like SGS, TÜV, or TestCoo for pre-shipment audits. For critical markets (e.g., Japan’s PSE certification), ensure inspectors are accredited by local bodies like METI

- Focus on AQL sampling and functional testing. For example, TestCoo offers real-time video inspections and LBS tracking for transparency.

6. Prioritize Suppliers with Overseas Market Experience

- Suppliers serving EU/US/Japan markets typically comply with stricter regulations (e.g., REACH, TUV/GS, or JIS certifications). For instance, a supplier familiar with EU battery regulations (webpage 1) or Japan’s PSE certification process (webpage 11, 15) will better navigate compliance hurdles.

- Check client portfolios for global brands

Additional Tips

- Audit On-Site: Use tools like Alibaba Supplier Assessment or conduct virtual audits via platforms offering live factory tours.

- Negotiate Contracts: Include penalties for non-compliance and rewards for zero-defect batches.

- Leverage Industry Networks: Attend trade shows like Canton Fair or use B2B platforms (Alibaba, Globalsources) with verified supplier badges.

By combining these steps, you’ll mitigate risks and secure suppliers capable of delivering high-quality stamping parts with consistent service.