Kingway Metal offers a comprehensive range of flight case hardware, including the crucial recessed lid stay, designed to provide robust support and protection for your valuable equipment. As a leading one-stop case hardware manufacturer, we understand the importance of reliable and durable components in ensuring the longevity and functionality of your flight cases and road cases. Our recessed lid stays are engineered to meet the demands of the most rigorous applications, offering a seamless blend of strength, security, and ease of use, especially when paired with our heavy-duty handles.

Understanding Recessed Lid Stay for Flight Case

What is a Recessed Lid Stay for Flight Case?

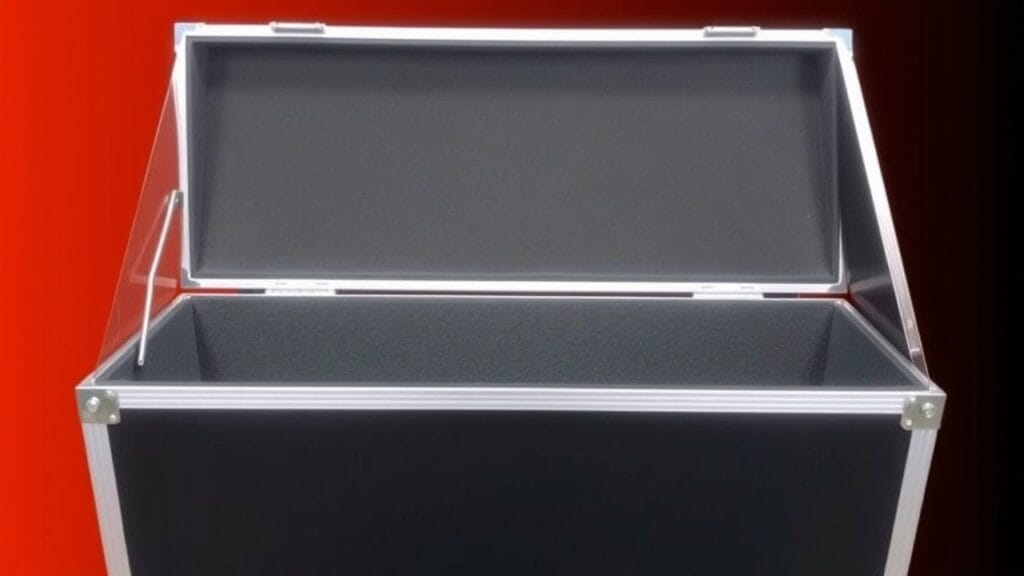

A recessed lid stay for a flight case is a piece of flight case hardware designed to hold the lid of a case open at a specific angle. The defining feature of a recessed lid stay is that it is designed to sit within a recess or a dish on the interior of the case or lid, allowing for a cleaner design with minimal intrusion from handles. This recess allows the stay to fold away neatly when the lid is closed, minimizing intrusion into the internal space of the case while accommodating heavy components. Recessed lid stays provide support and stability, preventing the lid from falling back unexpectedly, which could cause damage to the case, its contents, or even injury. Often used in conjunction with hinges, a lid stay ensures the lid remains securely open during use, making it an indispensable flight case part.

Benefits of Using Recessed Lid Stay for Flight Case

Using a recessed lid stay offers several key benefits for your flight cases and road cases, including improved handling and stability during transport. Primarily, it provides enhanced protection for the case lid and its contents by preventing uncontrolled movement. This is especially crucial during events or transport when the case might be subject to vibrations and impacts. The recessed design ensures that the lid stay doesn’t protrude into the interior of the case, maximizing usable space for equipment and foam inserts. Our heavy-duty lid stays are constructed from high-quality steel, offering exceptional durability and a longer lifespan. Furthermore, our extrusion options provide additional strength and durability. the secure fitting and reliable operation of a recessed lid stay contribute to the overall professionalism and user-friendliness of your cases. Our recessed lid stays provide a stronger hold and peace of mind.

Types of Lid Stays

Lid stays come in various sizes and materials to accommodate different case sizes and weight capacities. Kingway Metal offers a wide selection, including medium recessed and large recessed options, ensuring we have the perfect stay for your specific needs. The material used, typically steel, is chosen for its strength and durability, with different thicknesses available for varying levels of heavy-duty support. Some lid stays are designed for heavier lids, incorporating stronger mechanisms and more robust mounting holes to ensure a secure and lasting fit. The choice between different types of lid stays often depends on the case size, the weight of the lid, and the level of protection required. We offer lidstays compatible with Penn Elcom parts.

Choosing the Right Recessed Lid Stay for Flight Case

Medium vs. Large Recessed Lid Stay for Flight Case

When selecting a recessed lid stay for your flight case, consider the dimensions and weight of the case lid. To help you choose the right size, consider the following options:

- Medium recessed lid stays are ideal for smaller to mid-sized flight cases, providing ample support without being too bulky. They ensure the lid remains securely open without overwhelming the case’s design.

- Large recessed lid stays are better suited for larger, heavier lids commonly found on road cases. These heavy-duty stays offer enhanced strength and stability, preventing any unwanted movement during events or transport.

Evaluate your specific needs based on the case size and lid weight to determine whether a medium recessed or large recessed option is the most appropriate choice for heavy loads. Proper selection ensures reliable support and extends the lifespan of your flight case hardware.

Material Considerations for Recessed Lid Stays

The material composition of a recessed lid stay significantly impacts its durability and performance. While and High-quality steel is a common choice for lid stays, offering excellent strength and resistance to wear and tear. For humid conditions, stainless steel with a protective coating, such as black E-coating, provides superior corrosion resistance, ensuring a longer lifespan for the recessed lid stay. The thickness of the material also plays a crucial role, with thicker steel providing added heavy-duty support for heavier lids. Selecting the right material ensures your lid stay remains reliable and functional, providing lasting protection for your equipment and flight case parts.

Compatibility with Road Cases and Flight Cases

Ensuring compatibility between your recessed lid stay and the road cases or flight cases is crucial for optimal performance. Different cases may have varying mounting requirements, and it’s essential to choose a lid stay that fits seamlessly. The recessed dish should align properly with the case’s design, allowing the stay to fold away neatly when not in use. Check the dimensions of the lid stay and compare them with the available space inside the case. Some lidstays, like those compatible with Penn Elcom parts, offer standardized sizes and mounting holes, simplifying the installation process. When retrofitting or replacing a lid stay, ensure that the mounting points match or can be easily adapted. Proper fitting guarantees that the lid stay functions reliably, providing the necessary protection and support for your case lid and contents. Incorrect fitting can compromise the stay’s effectiveness and potentially damage the case or hinge.

Installation of Recessed Lid Stay for Flight Case

Tools Required for Installation

Before you begin installing your recessed lid stay, ensure you have the necessary tools at hand. You’ll need several items to ensure a smooth installation process, including heavy-duty handles and casters.

- A drill with appropriately sized drill bits for creating mounting holes for heavy components is essential for a secure fit.

- A screwdriver (Phillips and flathead) to secure the lid stay.

- Measuring tools, such as a ruler or tape measure, for accurate placement.

- A pencil or marker for marking drilling points.

- Safety glasses to protect your eyes during drilling.

Lastly, consider having a rivet gun or appropriate hardware for securing the lid stay, depending on your preferred method. With these tools, installing your flight case hardware will be a smooth and efficient process.

Step-by-Step Installation Guide

The first step in installing a recessed lid stay involves carefully measuring and marking the desired location inside your flight case or road cases. Position the recessed dish of the recessed lid stay against the inside of the case lid to determine the optimal placement for support and smooth operation. Once you’ve marked the spot, pre-drill the mounting holes using a drill bit that matches the size of your chosen mounting hardware. Next, align the recessed lid stay with the pre-drilled holes and secure it using rivets, screws, or bolts, ensuring a tight and durable fitting. Test the movement of the lid and the functionality of the lid stay to confirm it operates smoothly without any binding. Adjust the positioning as needed to achieve the desired angle and stability. This precise fitting ensures the reliable performance of the recessed lid stay, offering optimal protection for your equipment.

Common Mistakes to Avoid

When installing a recessed lid stay, one common mistake is failing to accurately measure and mark the mounting locations. This can lead to misalignment and a compromised fitting, reducing the effectiveness of the lid stay. Another error is using the wrong size drill bit, which can result in stripped mounting holes or a loose connection. Avoid overtightening the mounting hardware, as this can damage the case material or the lid stay itself. Neglecting to check the compatibility of the lid stay with the case size and lid weight is also a frequent oversight. Ensure the chosen recessed lid stay, whether medium recessed or large recessed, is appropriate for your specific application. Finally, always double-check the movement of the lid and the stay after installation to confirm smooth operation and reliable support. Avoiding these mistakes ensures a durable and reliable installation of your flight case hardware, protecting your valuable equipment during any event or transport.

Maintenance and Care for Recessed Lid Stays

Regular Maintenance Tips

To ensure the longevity and reliable performance of your recessed lid stay, regular maintenance is essential, especially if it supports heavy lids. A few key steps can help maintain optimal functionality:

- Periodically inspect the mounting points to ensure they remain secure. Tighten any loose screws or rivets to prevent wobbling or detachment.

- Clean the lid stay with a dry cloth to remove dust and debris, which can hinder its smooth operation. For steel components, consider applying a light lubricant to the hinge points to prevent rust and corrosion, especially in humid environments where heavy use is expected.

By following these simple maintenance tips, you can extend the lifespan of your flight case hardware and ensure that your lid remains securely supported during every event or transport.

Signs of Wear and Tear

Recognizing the signs of wear and tear on your is crucial for timely replacement and maintaining the integrity of your . Common indicators include stiffness or resistance when opening or closing the lid, which may suggest worn-out hinges or a heavy lid. Visible rust or corrosion on steel components can compromise the stay’s strength. Check for cracks or bends in the metal, especially around the mounting holes, as these can indicate structural weakness. If the lid stay no longer holds the lid securely open or if it exhibits excessive play, it’s a clear sign that the heavy hardware is failing and needs attention. Addressing these issues promptly ensures the protection of your equipment during transport, particularly when using heavy-duty casters.

When to Replace Your Lid Stay

Knowing when to replace your is essential for ensuring the safety and functionality of your. If you notice significant damage, such as cracks, bends, or severe corrosion, it’s time for a replacement. A lid stay that no longer provides adequate support, causing the lid to droop or fall unexpectedly, should also be replaced immediately. Additionally, if the mounting holes are stripped or the stay is excessively loose, it indicates that the fitting is compromised. Regular inspections can help identify these issues early on, allowing you to replace the flight case hardware, including handles and casters, before it leads to further damage or potential injuries. Timely replacement ensures your flight case remains reliable, secure, and equipped with a sturdy handle for easy transport.

Popular Brands and Products

Comparing Different Brands

When comparing different brands of it’s essential to consider factors such as quality, construction, and heavy-duty casters are essential for optimal performance. Look for brands that use heavy-duty steel with corrosion-resistant coatings to ensure longevity. Compare the mounting holes and mechanisms to ensure they offer a secure and stronger hold. Customer reviews and ratings can provide valuable insights into the reliability and durability of different brands. Consider whether the lid stay is compatible with other flight case hardware you may already be using, such as Penn Elcom parts. Evaluating these aspects helps you choose a recessed lid stay that meets your specific needs and provides reliable protection for your equipment in road cases and flight cases.

Where to Buy Quality Hardware

Finding a source for purchasing quality casters and other heavy-duty hardware for your flight cases. And other is crucial for ensuring the longevity and performance of your handle. As a leading one-stop manufacturer, Kingway Metal offers a comprehensive range of and components. Reputable online retailers and specialized flight case supply stores are also good options. Look for suppliers that offer detailed product specifications, customer reviews, and warranties to ensure you are investing in high-quality hardware, including handles and heavy-duty casters. Verify that the supplier is an authorized distributor for brands like Penn Elcom to guarantee authenticity. Purchasing from a trusted source ensures that you receive genuine, heavy-duty lid stays that provide the necessary support and protection for your valuable equipment during any event or transport.