Warmer and warmer climate, higher and higher requirements of flight case hardware on quality of zinc plating to have better corrosion resisitance capability.

As a manufacturer of flight case hardware, we recognize that zinc plating is one of the most critical processes in our production—especially as the climate becomes warmer and more humid.

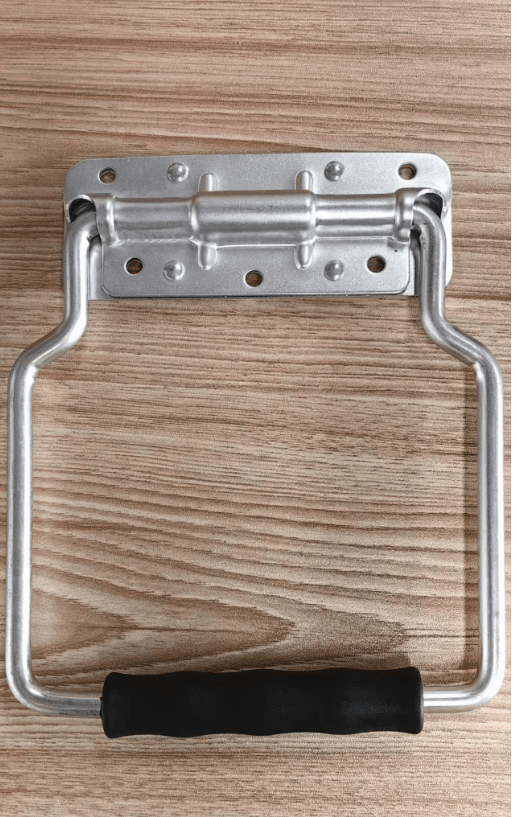

The two handles samples shown here, both from a European customer, were simply stored on a desk. The one on the left was received in May, and the one on the right in March. Despite not being exposed to harsh conditions, both handles show signs of surface corrosion.

In response to these environmental challenges, many of our subcontractors have reported that customers are increasingly demanding higher standards for zinc plating. For instance, the required salt spray test (SST) duration has been extended from 24 hours to 48 hours, and some extended it from 48 hours to 72 hours. This change comes as more customers have observed corrosion issues emerging more quickly this summer.

At this situation, our experience of construction products and door and window hardware is a great advantage to have the best zinc plating resources. The surface of our flight case hardware has a good ability for anti-corrosion.The long handle in picture was made by Kingway Metal 8 years ago, it’s still shining after long time.